The choice of spring materials should be determined according to the nature of the load borne by the spring, stress state, stress size, working temperature, environmental media, service life, requirements for electrical and magnetic conductivity, process performance, material sources and prices.

When determining the shape and size of the material section, priority should be given to the series size specified by national standards and ministerial standards, and non-standard series specifications should be avoided as far as possible.

Medium and small springs, especially spiral tensile springs, should be prioritized with strengthened steel wire, lead bath and other warm drawn steel wire and oil quenched tempering steel wire, with high strength and good surface quality, fatigue performance is higher than ordinary quenched tempering steel wire, simple processing, good process, stable quality.

The carbon spring steel wire and piano steel wire produce large residual stress after cold drawing, after processing the spring, there is a large residual stress, after tempering the size change is large, it is difficult to control the dimensional accuracy. Oil quenching tempering steel wire is modulated and strengthened after the steel wire is drawn to the specified size. Basically, there is no residual stress. After the molding spring is tempered at low temperature, the size changes are small, and the heat stability is better than that of cold drawn steel wire.

Large and medium-sized springs, for high load accuracy and stress should be selected cold drawn materials or cold drawn polished steel. For springs with low load accuracy and stress, hot-rolled steel can be used.

The leaf spring generally uses 55Si2Mn, 60Si2MnA, 55SiMnVB, 55SiMnMoV, 60CrMn, 60CrMnB and other grades of flat steel.

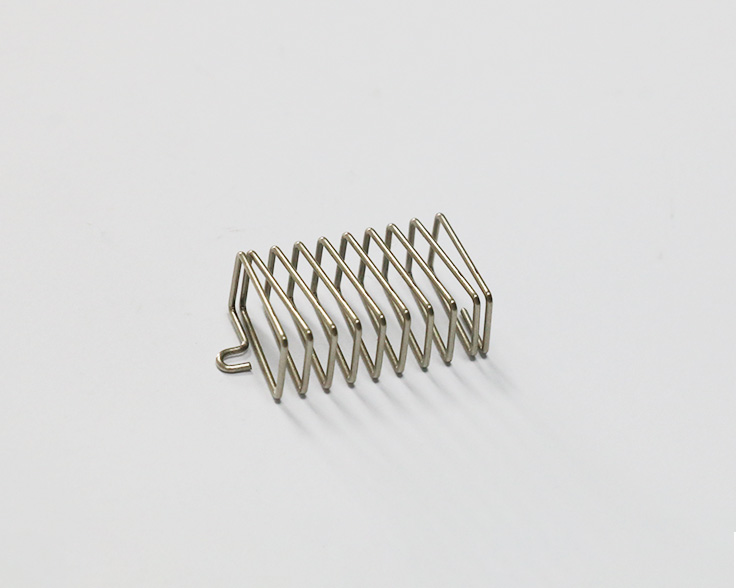

The material cross-section of the helical spring should be preferentially selected as a circular cross-section. Square and rectangular cross section materials have strong bearing capacity, good impact resistance, and can miniaturize the spring, but the material source is less. And the price is high, in addition to special needs, generally try not to choose this material. In recent years, the use of round steel wire flattening instead of trapezoidal steel wire has been developed, and good results have been achieved.

Spring materials that work at high temperatures require good thermal stability, resistance to relaxation or creep, oxidation resistance, and resistance to certain medium corrosion.

As the working temperature of the spring increases, the elastic modulus of the spring material decreases, resulting in a decrease in stiffness and a decrease in carrying capacity. Therefore, the spring working at high temperature must understand the rate of change (value) of the elastic modulus, and calculate the impact of the reduction of the bearing capacity of the spring on the performance of the service. According to the provisions of GB1239, when the working temperature of the ordinary helical spring exceeds 60℃, the shear modulus should be corrected, and the formula is: Gt= G in the formula of KtG -- the elastic modulus at normal temperature; Gt -- shear modulus at operating temperature t; Kt -- Temperature correction coefficient is selected according to Table 2-98.

The spring material used at low temperatures should have good low temperature toughness. Carbon spring steel wire, piano steel wire, 1Cr18Ni9 and other austenitic stainless steel spring steel wire, copper alloy, nickel alloy has good low temperature toughness and strength.

At low temperatures, the brittleness of the material is very sensitive to surface defects, so the surface quality of the material should be strictly required.

At low temperature, the corrosion degree of the environmental medium is much smaller than that under the greenhouse, and cadmium plating and zinc plating are easy to cause cold brittleness.

At low temperatures, the elastic modulus and expansion coefficient of the material change little and can not be considered in the design.

For springs made of spring steel, the choice of hardness (that is, strength) should be based on the bearing nature of the spring and the size of the stress. However, the level of hardness has a great relationship with the plane strain fracture toughness.

It can be seen from the curve relationship that the plane strain fracture toughness (KIC) value decreases significantly with the increase of hardness. This means that when determining the hardness value of the spring, it should be based on the premise of meeting the characteristics of the spring, the hardness value of the spring is lower.

When selecting spring materials, pay attention to the hardenability of steel. Whether the section of the spring material is quenched and the degree of quench is closely related to the quality of the spring.

Electrical springs that use the spring itself as a conductor or springs that work in water (including seawater) and water vapor environments under fluctuating humidity conditions are generally made of copper and gold.

Springs that work under acid contact and other corrosive media are generally made of corrosion-resistant materials such as stainless acid-resistant steel or nickel alloy. The spring used in the general environmental medium conditions is made of ordinary spring steel, and the surface is coated with anti-rust or electroplated (galvanized, cadmium plated, copper plated) to prevent corrosion.

In order to meet the accuracy of springs used in weighing instruments and instruments, constant elastic alloys with minimal changes in elastic modulus and expansion coefficient are generally selected in order to meet the impact of temperature changes.

In the requirements of light weight, insulation, anti-collision, anti-rust and other special purpose springs, you can choose reinforced plastics. At present, the more suitable plastic spring is made of epoxy resin, phenolic resin as the matrix, and glass fiber reinforced thermosetting reinforced plastic GFRP. Anti-vibration rubber can also be used to manufacture various types of rubber springs.

Mailbox:sales@sz-Zhaoneng,com

Contact number:+86 0512-66707386 +86 15262592017

Add: Building 7, Yajing High-tech Park, 161 Shilin Road, Suzhou New District