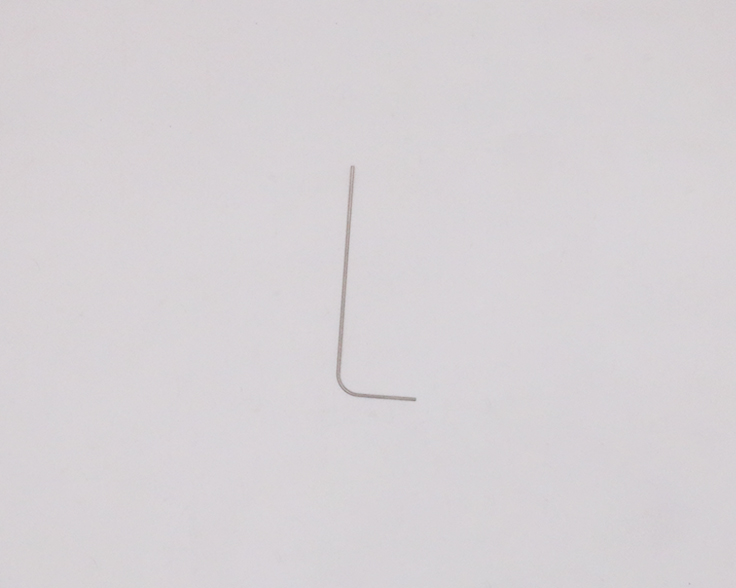

Burr is a common problem in the processing of special-shaped bending parts, mainly due to cutting, stamping, bending and other processes, if not handled in time, it will have a great impact on product quality and production efficiency. Here are several ways to deal with the burr problem:

1. Adopt appropriate mold and processing technology. Choose suitable materials, reasonable mold design and high quality processing equipment to avoid burr problems.

2. Adjust the cutting Angle and Angle rounding of the tool to reduce the cutting force of the tool on the edge of the material, so as to prevent the generation of burrs.

3. The use of sheet metal pretreatment process, such as pickling and deoxidation treatment, can remove impurities such as iron filings and oxides on the edge of the sheet to ensure good edge quality.

4. Automatic folding with bending mold. In the bending process, the automatic folding of the bending die can avoid manual wrong operation and reduce the generation of burrs.

5. Using grinding and polishing and other treatment methods. For the special-shaped bent parts with burrs, processing methods such as grinding and polishing can be used to ensure the smooth surface of the product and reduce the appearance of burrs.

Mailbox:sales@sz-Zhaoneng,com

Contact number:+86 0512-66707386 +86 15262592017

Add: Building 7, Yajing High-tech Park, 161 Shilin Road, Suzhou New District