As a common elastic element, springs play an important role in many mechanical devices and industrial production. In order to meet the needs of springs in different industrial and mechanical fields, it is necessary to produce high-quality and high-precision springs. Their production process is also different due to different materials, shapes, precision and other factors. Next, Suzhou spring manufacturers will explore several common precision spring production processes.

First, stretch spring production process

Tensile spring is also called tensile spring, and its production process is carried out by drawing, winding, heat treatment, passivation and other processes. The shape of the stretching spring is various, which can be linear spring, coil spring, hook and loop spring, etc. Different types of springs require different production equipment and processing processes to ensure product quality.

The production of tensile spring requires the use of high-quality materials, such as sine steel wire, alloy steel wire, etc., to ensure the performance of the spring. First, the spring steel is stretched by a stretch bending machine, and the tensile strength is adjusted on the equipment to ensure that each spring has the same strength. Next, the spring steel after stretching is wound into a long and thin cylinder by the bending machine to determine the length and diameter of the spring.

After winding, the spring needs to be heat treated, also known as passivation, and the spring steel is heated to make it have better elasticity and toughness, and stays at a specific temperature for a period of time, reducing the hardness of the spring steel and enhancing its flexibility. This can ensure that the spring elasticity is good, and the service life is longer. After the treatment is completed, the spring surface is chemically treated to supplement the surface material of the spring and increase the material thickness and corrosion resistance of the spring.

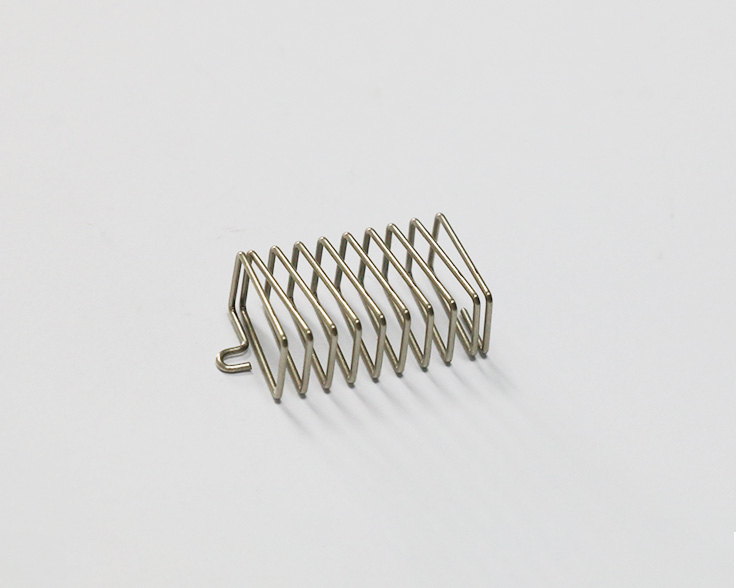

Second, torsion spring production process

Torsion spring is also a more common type of spring, and its production materials mainly include sine steel wire, alloy steel wire, stainless steel wire and so on. The production process of torsion spring is mainly divided into two parts - the winding and heat treatment of spring steel. The production of torsion springs requires the use of professional mechanical manufacturing equipment, such as mechanical torsion springs, and automatic heaters.

In the production of torsion spring, it is also necessary to use the production process of tensile strengthening, winding and shape trimming. The spring steel needs to be fed to the rotary spring through the fine thread cutting feed and the winding of the spring steel begins. In this process, the operator needs to set parameters such as the elastic modulus according to the requirements to ensure that the mechanical properties of the spring steel are only in line with the production needs. After the spring steel is finished winding, the manipulator usually moves the spring steel to a preset heat treatment area for constant temperature heating. The torsion spring requires high torsional rigidity and recoil strength. Heat treatment can increase the tensile strength of the spring steel and the torsion resistance of the spring.

Third, the production process of tension spring

A spring is a spring with great tensile strength in a straight line direction, usually used to support heavy loads or measure control forces. The production process of tension springs is similar to that of tension springs. The materials required to make the spring are mainly high-strength steel wire or stainless steel wire.

To make a spring, it is necessary to use a spring making machine to roll the spring on the workbench. The bending stroke should pass through the center line of the spring. After the spring steel material is wound into a spring of a certain thickness, it is processed mechanically to complete the bending, cutting, passivation and other work. When making the spring, the key data such as the strength, elastic modulus and measurement unit of the spring steel material are mainly checked. While ensuring high quality materials, it is also necessary to check the sensitivity and accuracy of the production machinery, so that the batch production meets the high quality standard and the operation is stable.

Four, spiral spring production process

Helical spring is a kind of high elastic spring which is widely used in various industrial manufacturing and daily necessities. Its production requires the use of customized tools and equipment, such as crimper and spring manufacturing equipment, in order to optimize product quality and production efficiency.

The first step in the production of coil springs is to select suitable materials such as hot dip galvanized or stainless steel for custom processing. In the production process, it is also necessary to measure the diameter and length of the spring steel material, design the parameters of the production equipment and processing tools. During the production process, the operator also needs to accurately calculate the production parameters such as the boost, elongation, strength and sensitivity of the spring to determine the relevant data such as the size of the spring and the number of coils. After the coil spring processing is completed, it is also necessary to check the basic parameters such as pressure testing, and ensure that the product leaves the factory in accordance with normative standards.

All in all, although the production process of precision springs is complex and changeable, only through reasonable technology and the selection of high-quality materials and other aspects of meticulous seiko can produce high-performance, high-quality springs.

Mailbox:sales@sz-Zhaoneng,com

Contact number:+86 0512-66707386 +86 15262592017

Add: Building 7, Yajing High-tech Park, 161 Shilin Road, Suzhou New District