Torsion spring is a kind of elastic element commonly used in machinery manufacturing, mainly used in mechanical transmission, agricultural machinery, household appliances, automobiles, instruments, precision instruments, toys, textile machinery, medical equipment and other fields. Its function is to store and release mechanical energy or heat energy through elastic deformation to meet the needs of mechanical transmission, with flexible, economic, practical and other characteristics.

First, the basic principle of torsion spring

The basic principle of torsion spring is to use the characteristics of metal elasticity to produce spring force, which converts force or torque into elastic potential energy, and thus has storage capacity. When the torsion spring is twisted, its shape changes, so it will also produce deformation energy, so that the torsion spring has the functions of absorbing shock, damping, eliminating resonance, maintaining constant force, adjusting torque and so on. The basic principle of the torsion spring is to coil a steel wire together to form a spring, and use the characteristics of the rotational elasticity of the steel wire to generate a spring force, which converts the force or torque into elastic potential energy, and thus has the storage capacity.

Second, the classification of torsion spring

1. Sort by material

(1) Conventional torsion spring: conventional torsion spring is usually made of round steel, strip steel or round wire.

(2) Stainless steel torsion spring: stainless steel torsion spring is mainly used in occasions with high corrosion resistance demand, such as medical equipment and other industries.

(3) High temperature torsion spring: high temperature torsion spring is used in high temperature occasions, such as trains, automobiles and other large equipment.

(4) Copper torsion spring: Copper torsion spring is usually used in electrical equipment or power tools and other fields.

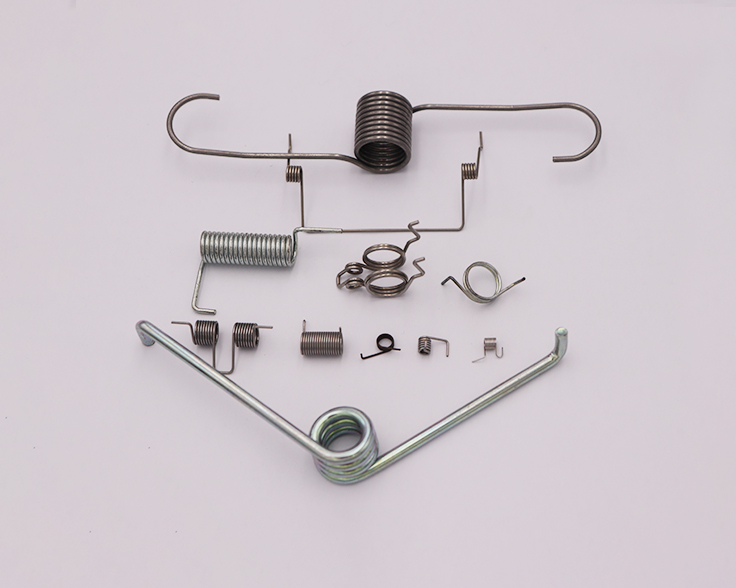

2. Sort by shape

(1) Direct torsion spring: the diameter and length are equal, simple and convenient, and widely used in various manufacturing and assembly.

(2) Locking torsion spring: the torsion spring cannot be restored after deformation by locking or shell processing to fix the relative position between the parts.

(3) Double torsion spring: the ingot and the cone use a reciprocal inversion structure, so that it will not be deformed in the case of strong torsion without torsion Angle.

(4) wing-free torsion spring: The elastic force of wing-free torsion spring can be released regularly or irregularly, and is usually used for short-distance power transmission and quantitative control.

(5) nested torsion spring: The nested torsion spring is formed by setting two or more torsion springs together, and its elasticity has both the winding force of the torsion spring and the pressure of the spring.

Third, the production process of torsion spring

The production process of torsion spring mainly includes design, material selection, processing, heat treatment, quality inspection and other links.

1. Design: According to the required elastic demand, calculate the flexural strength, torque, elastic coefficient and other indicators of the torsion spring.

2. Material selection: Select materials according to different performance requirements, such as ordinary steel, stainless steel, ordinary copper, phosphor bronze, zinc aluminum alloy, etc.

3. Processing: According to the design requirements, the steel or other materials are processed into the desired shape.

4. Heat treatment: The processed torsion spring is heat treated, the steel or other materials are heated to a certain temperature, and then cooled to improve its elastic strength and hardness and other properties.

5. Quality inspection: Quality inspection of the made torsion spring, including specific elastic force, diameter reduction rate, rebound rate, breaking strength and other indicators.

Mailbox:sales@sz-Zhaoneng,com

Contact number:+86 0512-66707386 +86 15262592017

Add: Building 7, Yajing High-tech Park, 161 Shilin Road, Suzhou New District